Indorama started the manufacturing of “Veola” contamination free combed compact yarns in 2008, in the city of Purwakarta, Indonesia. At present, “Veloa” is produced in 5 manufacturing units with a total output of 3500 MT every month.

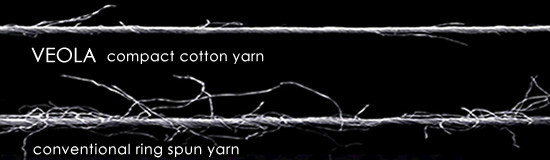

The “Veola” compact yarns are produced in Indonesia with a mix of cotton mechanically picked from different origins viz, USA, Australia, Brazil and Greece. Indo-Rama takes pride in seeing its role as a comprehensive architect for production of Veola in its production facilities equipped with state-of-the-art equipment from Trutzlschler, Rieter, Zinser Saurer, Toyoda, Murata and Schlafhorst.

Indorama ensures full transparency in the cotton used for manufacturing of Veola yarns with traceability documents available from yarn to cotton ginning.

Veola yarns are available with certifications from Better Cotton Initiatives (BCI), Cotton USA and U.S. Cotton Trust Protocol.