The fiber is spun into yarn or thread and used to make a soft, breathable textile. It is the most widely used natural-fiber cloth in clothing today.

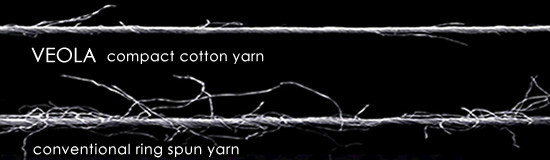

Cotton fiber, once it has been processed to remove seeds and traces of honeydew, protein, vegetable matter and other impurities, consists of nearly pure cellulose. Cotton fiber processing is very efficient with approximately ten percent of weight being lost in conversion of the raw Cotton bolls (seed cotton) into pure fiber. The cellulose is arranged in a way that gives Cotton fibers a high degree of strength, durability, and absorbency. Each strand is made up of twenty to thirty layers of cellulose coiled in a neat series of natural springs. When the Cotton boll is opened, the fibers dry into flat, twisted, ribbon-like shapes and become kinked together and interlocked. This interlocked form is ideal for production of Veola using Rieter technology of fiber processing.