Indorama's commitment to stringent standards of manufacturing, careful selection of raw material and innovative work practices makes Veola one of the most desirable yarns in the world.

Based on the various case studies conducted at some of the places, Veola is proven to offer distinct advantages to knitters and weavers in fabric production and wet processing and few of these are.

knitting

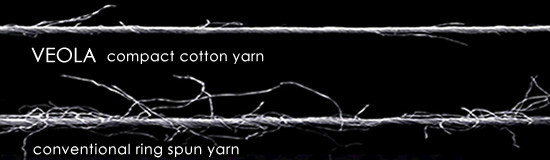

- Parallel fibers structured in the yarn body

- Most of the fibers contribute to the yarn properties

- Lower yarn imperfections

- Enhanced fabric appearance with reduced hairiness on fabric surface

- Reduced dust and fiber fly leading to better knitting efficiencies

- Reduced breakage at knitting machines causing less fabric holes

weaving

- Higher efficiency in warping and weaving machines due to lower abrasion among yarns

- Higher yarn strength and better elongation

- Lower sizing cost

- Fewer end downs resulting into higher efficiencies

- Improved final fabric appearance

wet processing

- Lower singeing cost due to reduced hairiness in fabric

- Lower dyeing cost due to deeper dye stuff penetration

- Cost saving due to reduced enzyme usage and garment weight loss